Tray sealing machines are essential equipment for food manufacturers aiming to enhance product shelf life, maintain freshness, and deliver professional-quality packaging. Rocket Machine Works specializes in reliable tray sealing machinery tailored for food processors, including ready meals, deli items, and specialty food products. Among their offerings, the Square Cut and Die Cut tray sealers stand out as two distinct solutions designed for different packaging requirements and production environments.

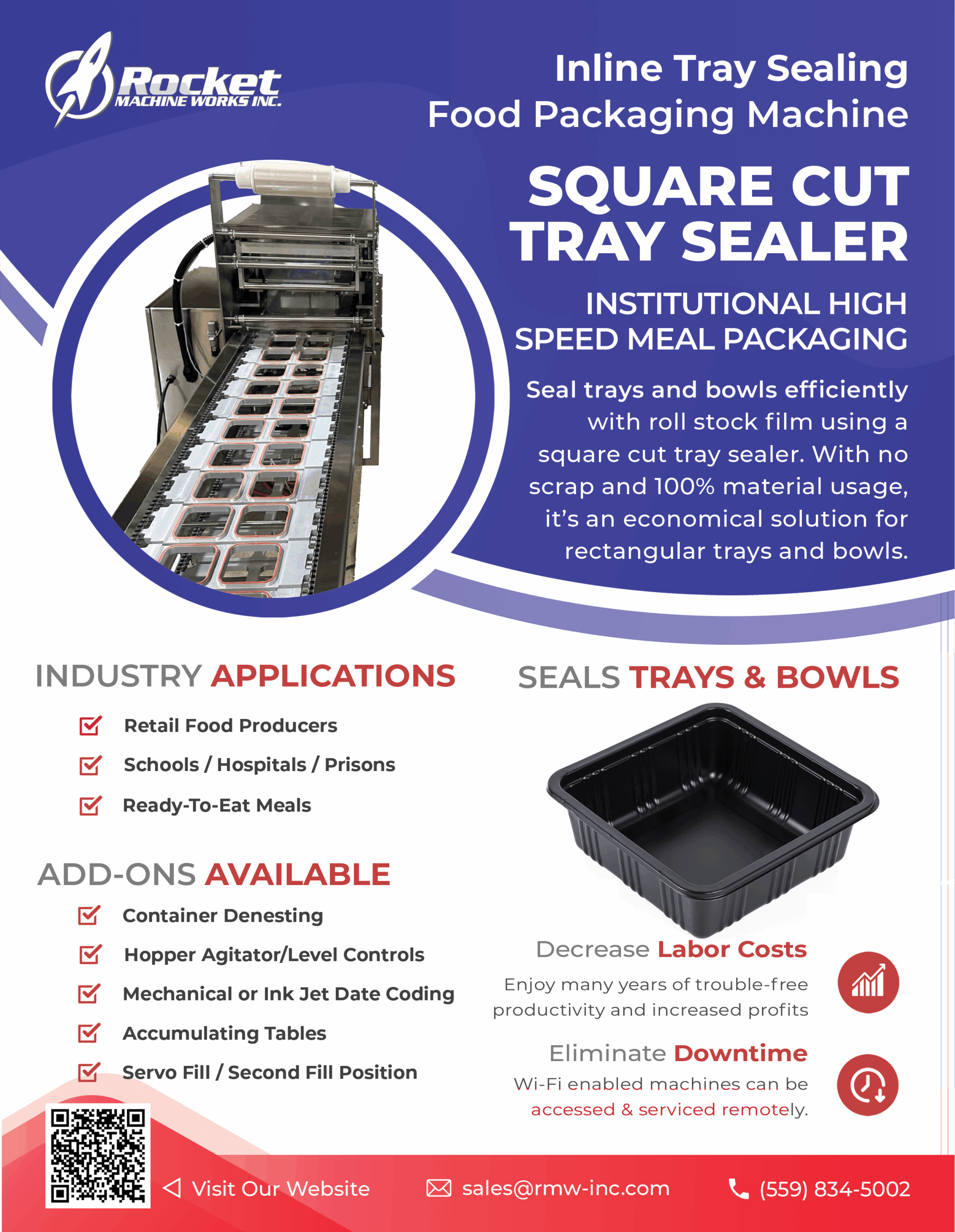

Understanding the Square Cut Tray Sealer

The Square Cut Tray Sealer (STS) is designed primarily for sealing trays that are square, rectangular, or have multiple compartments. Unlike standard cup sealers, this machine seals roll stock film to the tray and then performs a precise square trim around the perimeter of the film. This method ensures 100% film usage with no scrap, maximizing efficiency and reducing waste.

Key Features and Benefits of the Square Cut Tray Sealer:

-

Precision Aesthetics: Clean, squared edges provide a professional, uniform look that enhances product presentation.

-

Sealing Integrity: Provides a strong, airtight seal critical for extending shelf life and tamper-evidence.

-

Perfect for Multi-Compartment Trays: Ideal for ready meals, deli salads, and fresh produce packaging.

-

Durability and Compliance: Constructed with stainless steel and adhering to USDA, FDA, and NSF standards to ensure longevity and food safety compliance.

-

Ease of Integration: Designed for manual or conveyor-fed trays, making it flexible for different production line setups.

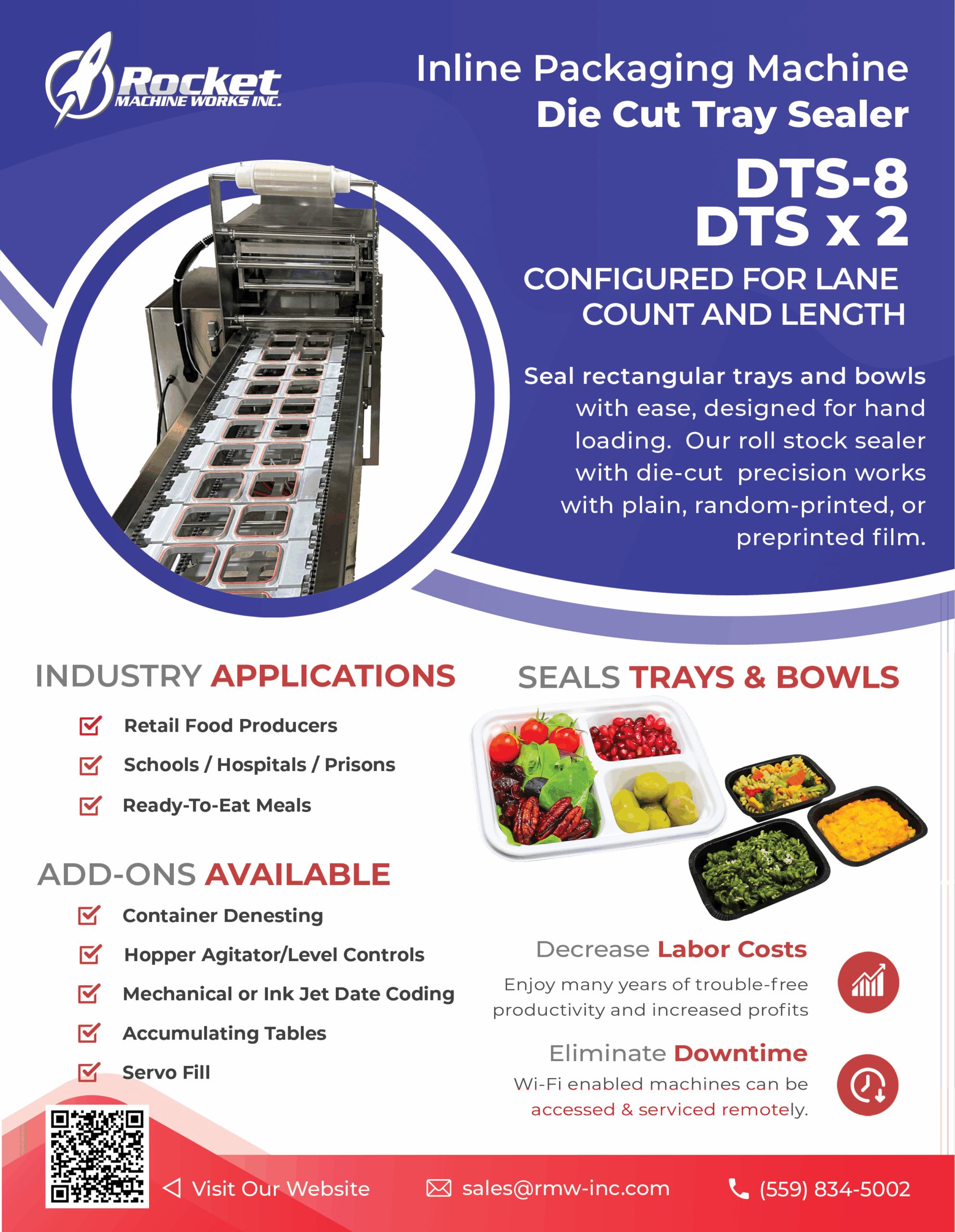

Understanding the Die Cut Tray Sealer

The Die Cut Tray Sealer (DTS) offers a premium sealing solution using a roll-stock sealing film that is applied to the tray and precisely trimmed to the exact contour of the container. This method results in a clean, contoured edge that follows the perimeter shape of trays, bowls, or other containers, delivering a polished look with minimized film waste.

Key Features and Benefits of the Die Cut Tray Sealer:

-

High Precision Finish: The die cut trimming matches tray shapes exactly, delivering premium aesthetics ideal for high-end packaging.

-

Scrap Take-Up System: Collects excess film scrap efficiently, reducing floor clutter and manual handling.

-

Versatility: Can handle plain, random print, or registered pre-printed film for perfect brand alignment.

-

Flexible Multi-Lane Operation: Can seal up to six containers per cycle at speeds ranging from 10 to 30 cycles per minute.

-

Strong Compliance and Sanitary Design: Features stainless steel construction, IP67-rated washdown components, and USDA/FDA/NSF compliance for rigorous food safety standards.

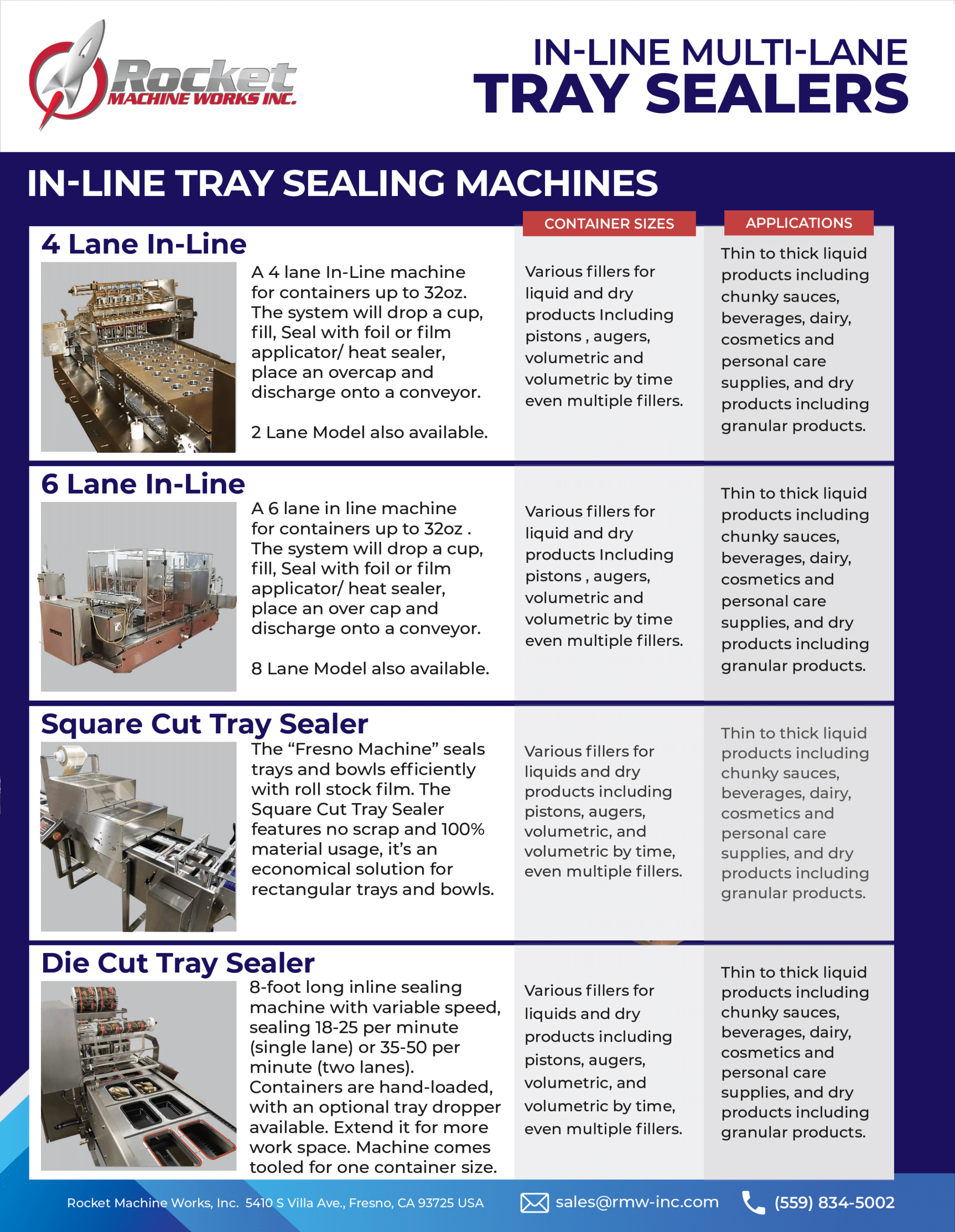

Side-by-Side Comparison

| Feature | Square Cut Tray Sealer | Die Cut Tray Sealer |

|---|---|---|

| Film Cutting Style | Square, clean trimmed edges | Die cut contour matching tray shape |

| Film Waste | No scrap, 100% film usage | Scrap take-up system for film waste management |

| Container Types | Square, rectangular, multi-compartment trays | Rectangular, oval, bowls, and uniquely shaped trays |

| Ideal Applications | Ready meals, deli salads, produce | Premium packaging, brand-aligned sealing |

| Speed | High throughput, multiple trays per cycle | Moderate cycles per minute, multiple lanes possible |

| Film Compatibility | Plain or random print film only | Plain, random print, and registered pre-printed film |

| Cleanability & Sanitary Standards | Stainless steel, USDA/FDA/NSF compliant | Stainless steel, washdown, USDA/FDA/NSF compliant |

| Integration Flexibility | Manual or conveyor-fed | Inline integration with servo index control |

| Production Efficiency | Maximizes film usage, reduces waste | Precise contour fit, less film waste, neat scrap handling |

Which Tray Sealer Is Right For You?

When deciding between a Square Cut and a Die Cut tray sealer, consider the following:

-

Packaging Shape and Presentation: If your trays are simple square or rectangular shapes with multiple compartments and you want to minimize plastic waste, the Square Cut model is efficient and produces neat results.

-

Branding and Premium Finish: For shaped trays (oval, contoured) or if branding aesthetics with printed film are critical, the Die Cut tray sealer delivers precision and professional appeal.

-

Production Volumes and Line Integration: The Square Cut sealer supports high throughput with multiple trays sealed at once, fitting well in high-volume institutional or ready-meal production. The Die Cut sealer is suitable for moderate to high production lines requiring inline sealing with precision control.

-

Waste Management: If minimizing scrap and conserving film is a priority, Square Cut offers 100% film use; however, Die Cut’s scrap collection system ensures easy handling of excess material.

-

Compliance and Food Safety: Both models meet industrial standards including USDA, FDA, and NSF, ensuring hygiene and reliability in food processing environments.

Frequently Asked Questions

What types of films can I use with these tray sealers?

The Square Cut Tray Sealer works with plain or random print roll stock films. The Die Cut Tray Sealer supports plain, random print, and registered pre-printed films, enabling detailed brand registration.

Can these machines handle multi-compartment trays?

Yes, the Square Cut Tray Sealer is specifically designed for multi-compartment trays, making it ideal for ready meals. The Die Cut machine is versatile but typically more suited for complex or uniquely shaped trays.

How fast can these machines seal trays?

Square Cut models can seal multiple trays per cycle, facilitating high throughput suitable for institutional packaging. Die Cut models operate at 10 to 30 cycles per minute, sealing up to six containers per cycle depending on tray size.

Are the machines easy to clean?

Both machines feature stainless steel construction with washdown components designed for quick cleaning, meeting the sanitation standards required by USDA, FDA, and NSF.

Can I use these machines with existing packaging lines?

Yes, both models are designed for seamless integration. The Square Cut can be fed manually or by conveyors, while the Die Cut Tray Sealer features inline servo index control for synchronized production lines.

Where are these machines manufactured?

Rocket Machine Works designs, engineers, and manufactures these tray sealers in California, USA, emphasizing reliability and local support.

Your Next Step in Tray Sealing Excellence

Choosing the right tray sealing machine depends on your specific packaging needs, production speed requirements, and the desired visual appeal of your product. The Square Cut Tray Sealer offers efficiency, minimal waste, and excellent sealing for square and multi-compartment trays. The Die Cut Tray Sealer provides superior contour sealing, versatile film compatibility, and premium aesthetics for shapes that require a tailored approach.

For food processors seeking dependable, customizable packaging machines made in the USA with strong reliability and service support, Rocket Machine Works is a leading partner. Contact their expert team to discuss your production goals and find the perfect tray sealing solution for your operation.