Ensure Accurate Coding with the Videojet Date Coder

Streamline your food production with precision and reliability.

Effortless Date and Lot Coding for Food Manufacturers

The Videojet Date Coder is the essential addition to your filling and sealing line, designed to help food manufacturers efficiently code critical information like dates, lot numbers , and tracking details onto every container. Whether you’re running a single machine or an entire production line, this coder integrates seamlessly to boost your productivity, reduce labor costs, and ensure compliance with labeling standards.

Enhance your operations and reduce downtime with the reliable coding solution your business deserves.

[Request a Quote Today]

Why Choose the Videojet Date Coder?

Unmatched Precision and Flexibility

- Easily print production dates, expiration dates, and lot numbers with consistent accuracy.

- Display additional tracking data like percentage values and other metrics , improving traceability and operational insights.

Seamless Integration

- Designed to work perfectly with your new or existing production line , even with food packaging machines not built by us.

Optimized for Efficiency

- Reduce operator intervention with an intuitive interface that simplifies coding tasks.

- Durable and reliable construction minimizes unplanned downtime.

Customizable for Your Needs

- Adaptable coding options tailored to meet your specific production demands.

How It Works

1. Integrate with Your Line

The Videojet Date Coder fits easily with your existing systems, simplifying the setup process for quick implementation.

2. Configure Your Codes

Set your desired formats, including production time, lot numbers, and expiry dates, with precision.

3. Achieve Reliable Results

Every code is printed accurately and efficiently, ensuring compliance and meeting industry standards with ease.

[Get Started Today]

Trusted by Food Manufacturers Nationwide

“Adding the Videojet Date Coder to our production line has been a game-changer. The precision of the codes and seamless integration with our machines keep our operations running smoothly.”

– Operations Manager, Deli Salads Inc.

“We needed a coder that could handle fast speeds without errors. The Videojet delivers on every promise.”

– Production Line Manager, Simply Fresh

[See More Customer Success Stories]

Frequently Asked Questions

Can the Videojet Date Coder integrate with any production line?

Yes, the Videojet Date Coder is designed to integrate with both new and existing production lines, even if your machinery wasn’t originally built by us.

What types of codes can it print?

It can print a variety of codes, including production dates, lot numbers, expiry dates, and other relevant tracking information tailored for food manufacturers.

How long does setup take?

Setup is straightforward, and our team is available to ensure your coder is operational as quickly as possible, minimizing downtime.

Is the coder compatible with multiple container types?

Yes, it works seamlessly with a wide range of container shapes and materials, making it versatile for various food production needs.

[Contact Us for More Information]

Take Control of Your Product Coding Today

Ensure precision, seamless integration, and compliance with the Videojet Date Coder . Improve your production efficiency and maintain trusted operations with a solution built for reliability and performance.

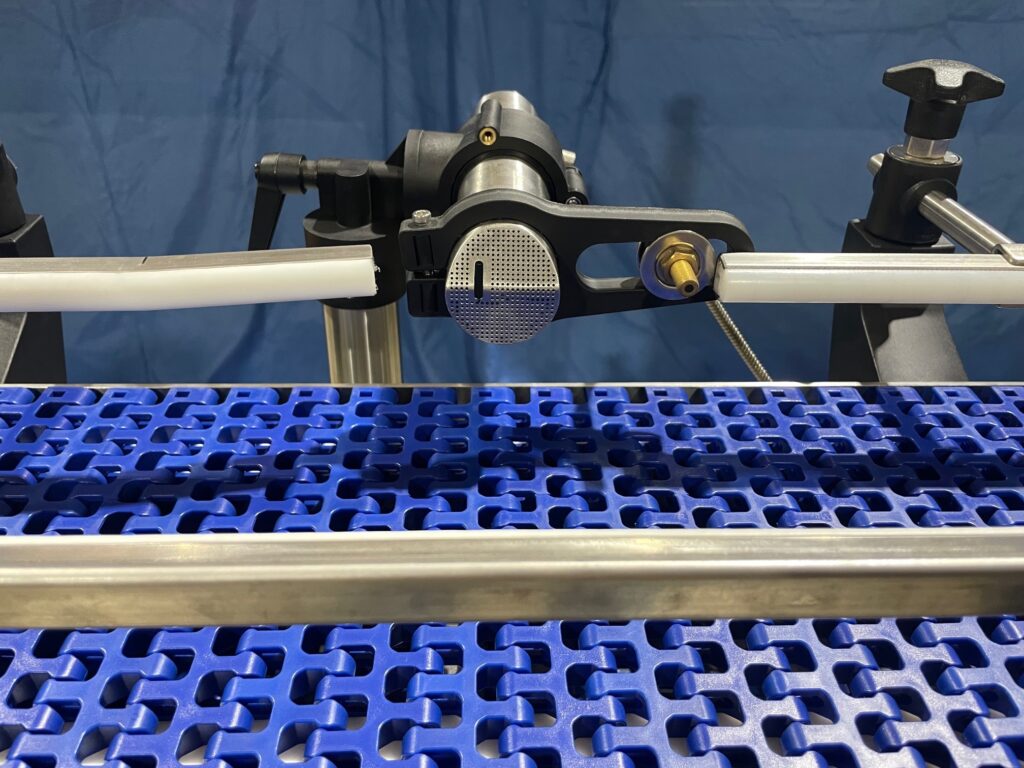

See Videojet Date Coder photos

Videojet 1880 + Continuous Inkjet Printer

The Videojet 1880+ Continuous Inkjet Printer, built on the high-speed 1880 platform, offers advanced non-contact printing on various substrates, including flat and curved surfaces. It supports intelligent plant operations with features like vital sign monitoring, smart alerts, remote support, and advanced troubleshooting. Equipped with an ink build-up sensor and the Videojet MAXIMiZE™ diagnostics suite, it helps minimize unplanned downtime. Additionally, its reduced ink consumption and precise drop placement enhance sustainability by cutting waste and conserving resources.

Need something custom designed?

Contact us with the details so we can line you up with the best machine possible for your production.