Elegant Engineering Meets Operational Efficiency

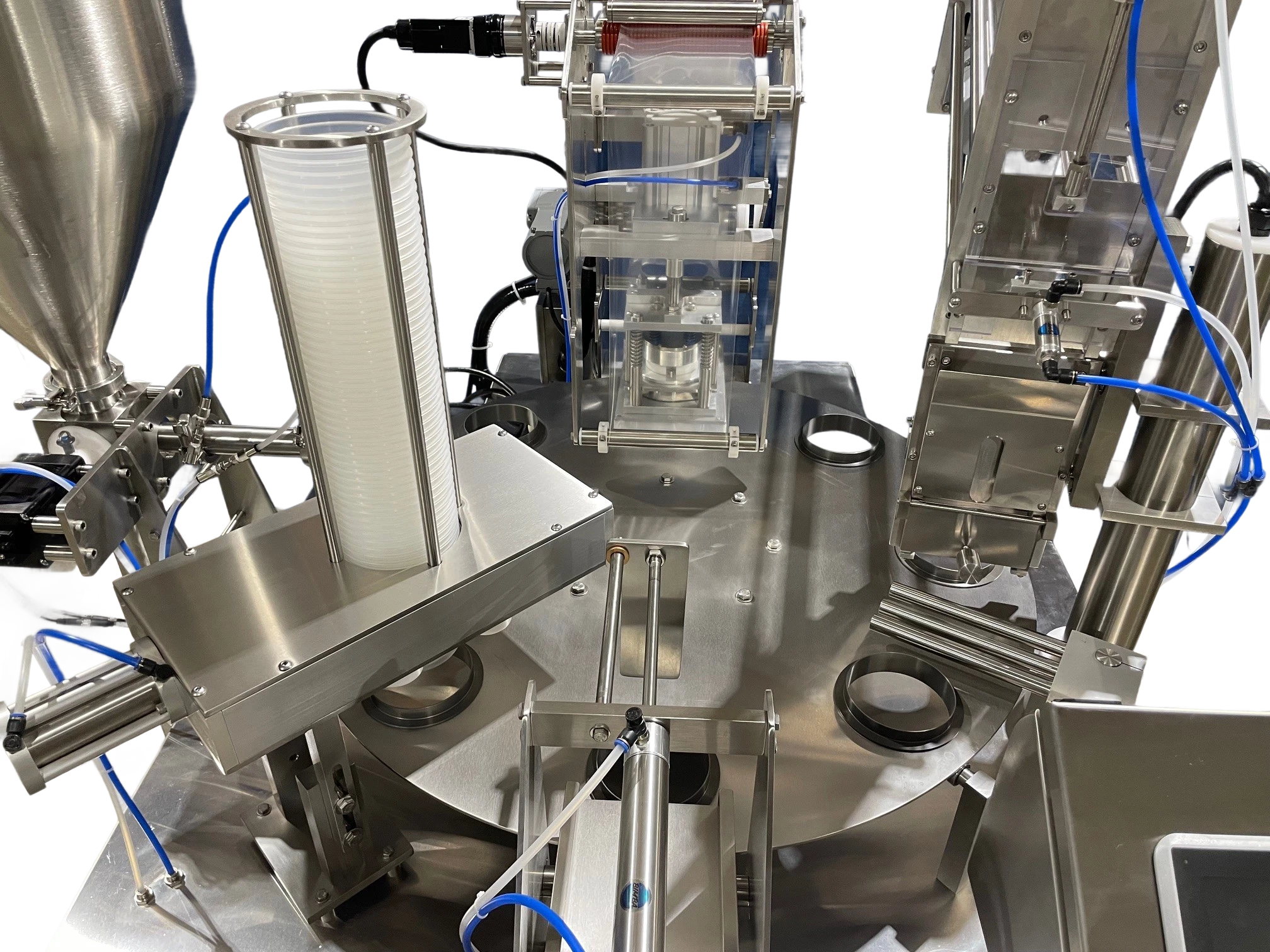

An eight-position rotary cup filler for die-cut foils or roll stock film with die cut.

Superior Production Speed

One Machine Can Be Configured to Fill & Seal 10-30 cycles Per Minute

*Depending on product and volume. For precise speed of operations:

Call To Ask

559-834-5002

Customized for cups and containers of larger sizes and volumes:

- Cups: 51 mm – 5″ diameter

- Square Containers: 4.75″ x 4.75″ max

- Max Volume: 32 oz

Features include:

- Container Denesting

- Servo Fill

- Second Fill Position

- Roll Stock Seal or Pick and Place Seals

- Pre-Printed Film

- Pick and Place Overcap

- Spinning Rail Overcap

Add-Ons Available:

- Pick and Place Seals

- Hopper Agitator/Level Controls

- Mechanical or Ink Jet Date Coding

- Accumulating Tables

- Cappers/Lidders

Meets Or Exceeds Standards

- USDA

- FDA

- NSF

Container Types (Cups & Containers)

- Deli Cups

- Sustainable Packaging

- PET Series

- Polyethylene /Polypropylene

Service & Support

- Eliminate Downtime. Each machine has a remote access module that allows us to fix and clear issues remotely. No need to wait for a service tech to come to your location.

Reduce Labor Costs. Scale Instantly With Additional Machines. Choose an Existing Design, or Custom Built For Your Exact Needs

The reason most companies buy our predictable, dependable machinery is to save hundreds of thousands of dollars per year on labor costs.

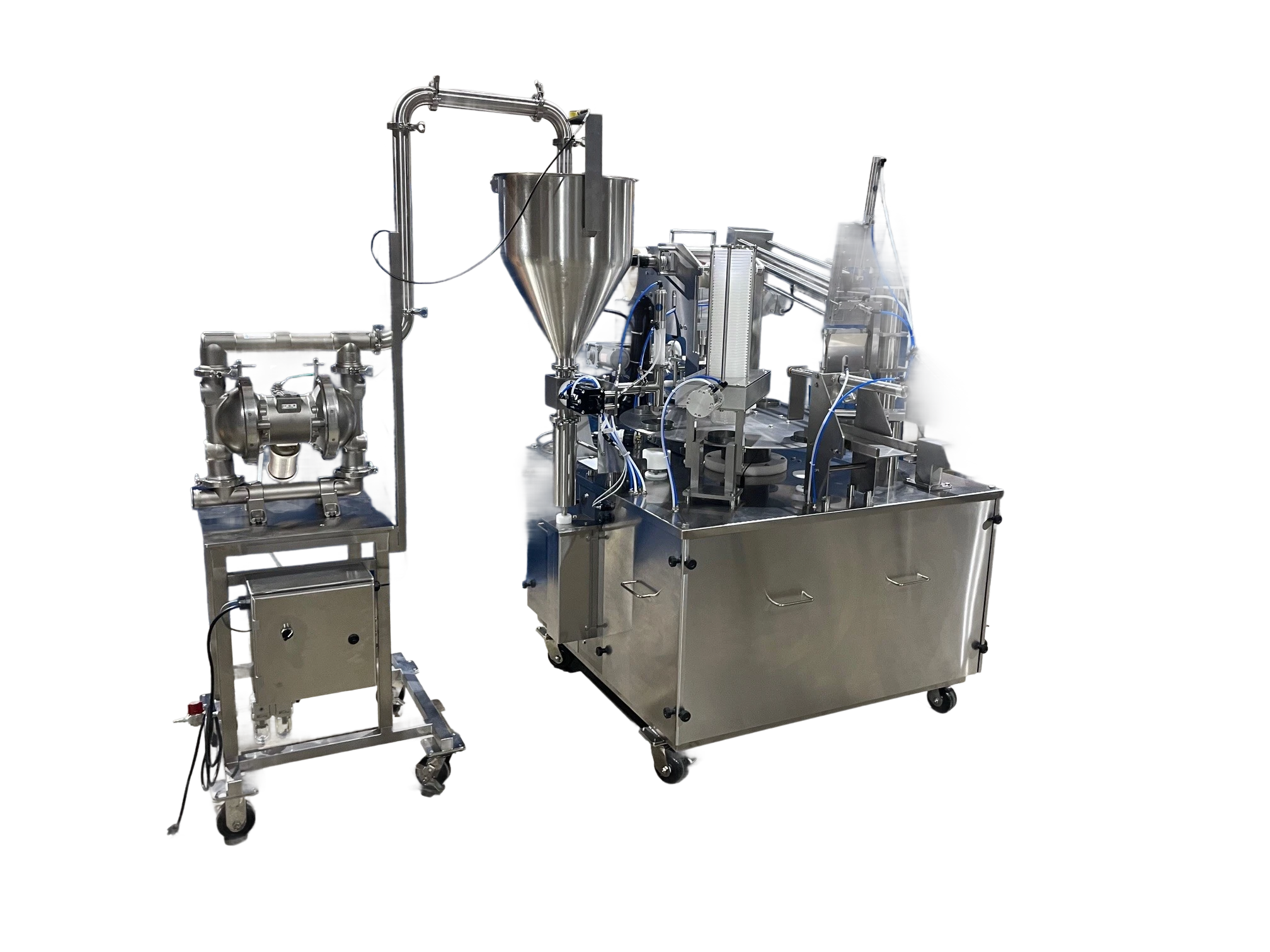

The RM-36 rotary filling and sealing packaging machine offers you a durable, efficient solution when you need solid production without compromising floor space. Made to meet or exceed FDA, NSF and USDA standards, these machines all have stainless steel construction and direct wash down components designed for sanitizing. We build several sizes depending on your production requirements, from only one container per cycle to as many as three containers per cycle. Features include cam index and lift motions, no container no fill, no container no seal, and other add-ons such as hopper agitator/level controls, CIP filling stations, mechanical or ink jet date coding, and accumulating tables.

RM-36 Rotary Filling and Sealing

Packaging Machines in Action

Perfect Seal Every Time

100% Air Tight. Plastic or Foil.

Optional: Roll Stock Film “Clear or Random Printed”

Expandable Production

As many as 3 containers per cycle depending on their diameter. Optional 2nd & 3rd Fill Positions.

Installation and Training

Our high quality manufacturing standards are only outmatched by our support and service excellence.

Frequently Asked Questions: RM-36 Rotary Filling & Sealing Packaging Machine

1. What types of products can the RM-36 Rotary Filling and Sealing Packaging Machine handle?

The RM-36 rotary filling and sealing machine is designed to package a wide range of products, including food items like hummus, yogurt, dips, deli salads, sauces, desserts, and dairy products, as well as non-food products such as saline solution.

2. What container sizes and shapes are compatible with the RM-36?

The RM-36 supports cups and containers ranging from 51 mm to 5 inches in diameter, square containers up to 4.75″ x 4.75″, and volumes up to 32 oz. This flexibility makes it ideal for deli cups, jars, PET, polypropylene, and sustainable packaging.

3. What output speeds can be expected from the RM-36 Rotary Filler Sealer?

Depending on your chosen configuration and product fill speed, the RM-36 achieves high production rates of 10 to 30 cycles per minute, with the ability to fill and seal up to three containers per cycle for higher throughput.

4. Is the RM-36 Rotary Filling and Sealing Machine suitable for food-grade applications?

Yes, the RM-36 is manufactured to meet or exceed USDA, FDA, and NSF food safety standards. All components feature stainless steel construction and washdown capability to support hygienic operations in food environments.

5. How does the RM-36 reduce labor costs and boost efficiency?

The RM-36 automates container filling, sealing, and discharge, minimizing manual labor and reducing operational costs. Many customers report saving hundreds of thousands of dollars per year by upgrading to our dependable rotary filling and sealing machinery.

6. Can the RM-36 be customized for unique packaging requirements?

Absolutely—the RM-36 rotary filling machine offers multiple customization options, including container denesting, servo fill, second fill positions, pick and place seals, overcap, hopper agitator, and date coding systems to meet diverse production needs.

7. What is the maintenance and service process for the RM-36 packaging machine?

Each RM-36 machine is equipped with a remote access module, allowing our team to troubleshoot and resolve issues instantly without on-site visits. This helps eliminate downtime and ensures continuous, reliable operation.

8. What is the price range of the RM-36 Rotary Filling and Sealing Machine?

Pricing for the RM-36 varies depending on the specific model, add-ons, and customization required for your production line. Rocket Machine Works offers solutions that provide exceptional long-term value, helping you maximize output and reduce labor costs. For precise pricing and a tailored quote, please contact our sales team directly.

9. Does the RM-36 Rotary Filler support different sealing methods and film types?

Yes, our rotary filling machines can be configured for roll stock film, pre-printed films, plastic, or foil, with options for pick and place seals or spinning rail overcaps, ensuring a perfect air-tight seal every time.

10. What installation and training support is available for the RM-36?

Rocket Machine Works provides professional installation and in-depth operator training to ensure your team can run the RM-36 efficiently and safely. Our commitment to service and support extends from setup through the entire lifetime of your equipment.