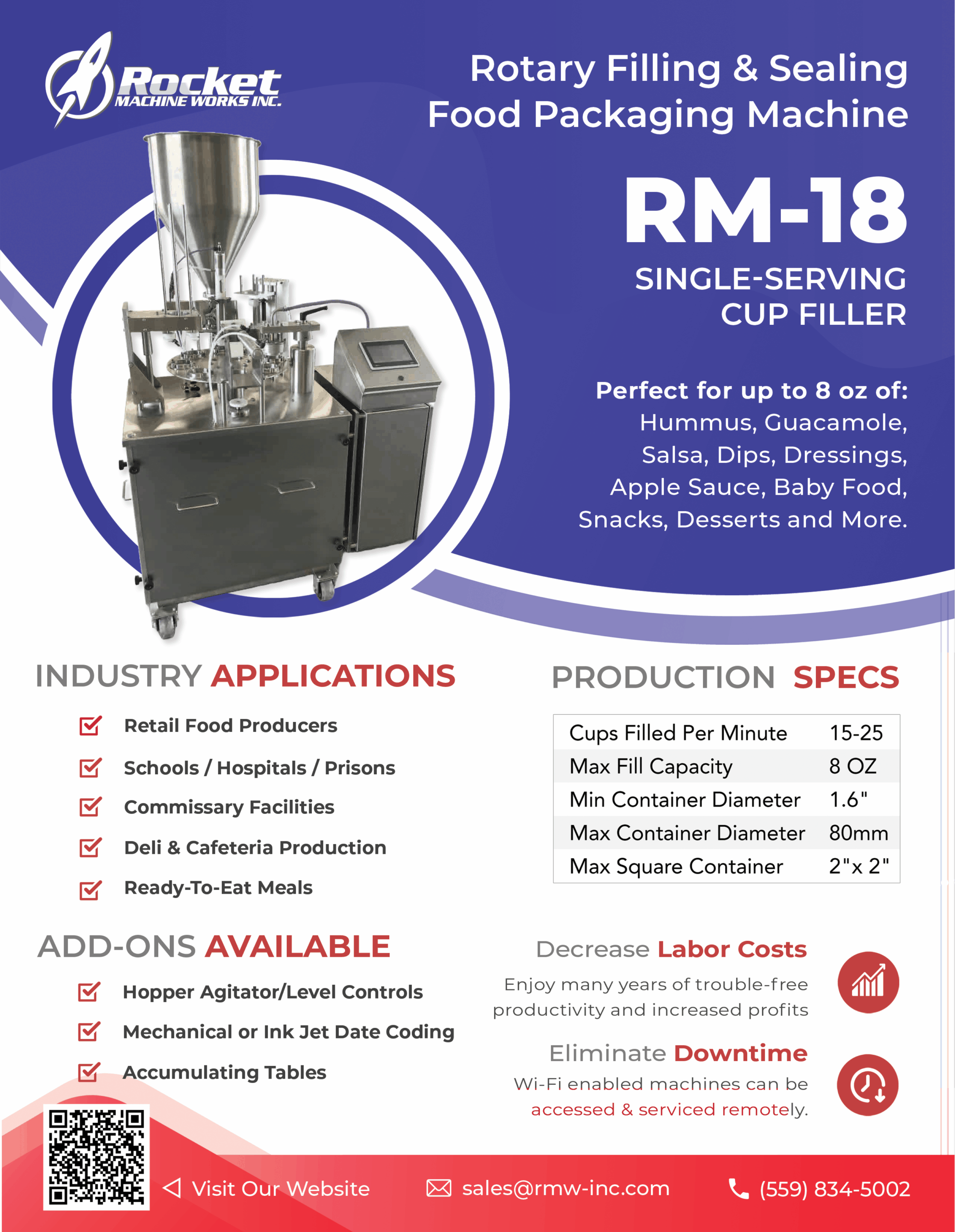

The RM-18: Precision Rotary Filling and Sealing for Optimized Production

For operations in food, dairy, deli, and specialized packaging, operational success hinges on speed, consistency, and strict regulatory compliance. These factors are non-negotiable foundations for production efficiency and customer satisfaction. That is why industry leaders rely on the RM-18 Rotary Filler and Sealer from Rocket Machine Works. Engineered for utility, the RM-18 is designed to perform one function with exceptional reliability: execute precise cup filling and sealing at volumes dictated by demanding production schedules.

Performance Metrics That Matter

The RM-18 is structured around an eight-position rotary platform, delivering consistent output of 15 to 25 cups per minute , adjustable based on specific product viscosity and fill volume. It manages a wide range of products, from yogurts and sauces to dips and complete meal preparation containers, maintaining a steady, repeatable rhythm. Critical to its performance is the servo-driven fill system , which ensures metered dosing is accurate and uniform across every batch.

A key differentiator is the RM-18’s robust container versatility. It accommodates round cups (from to mm in diameter) and square containers up to , with a maximum fill capacity of oz. The system can be rapidly configured to integrate seamlessly with your existing packaging inventory.

Minimizing Overhead and Maximizing Control

The high costs associated with manual labor and the inherent inefficiencies of manual packaging pose significant challenges. The RM-18 provides automated solutions to mitigate both.

The system features automatic container denesting , eliminating the need for manual cup loading. Its sophisticated pick-and-place sealing mechanism applies plastic or foil lids, guaranteeing a perfect, airtight seal on every cycle. Furthermore, the embedded control logic, “no container, no fill; no container, no seal” , prevents the waste of costly product and packaging materials on misfeeds.

Constructed entirely with stainless steel and wash-down-ready components , the RM-18 facilitates efficient sanitation protocols, ensuring compliance with the stringent hygiene standards mandated by regulatory bodies and expected by consumers.

Integrated Compliance and Safety

Food safety is a core engineering principle, not an accessory. The RM-18 is manufactured to meet or exceed USDA, FDA, and NSF requirements , allowing for operation with total confidence. It is fully compatible with standard packaging substrates, including deli cups, PET containers, and polyethylene/polypropylene options, as well as many contemporary sustainable alternatives.

Engineered for Scalable Growth

Business growth should not necessitate the replacement of capital equipment. The RM-18 is designed for future expansion. Depending on container dimensions, it can process up to three cups per cycle . Customization options include adding supplementary fill stations for layered products or dual sauces, selecting mechanical or reliable inkjet coding for batch and expiration printing, and integrating an agitator or level control to manage product flow issues in the hopper. For integration into a fully automated line, accumulating tables ensure smooth downstream flow.

The inherent modularity allows production capacity to be increased by adding units as demand rises, ensuring a low-disruption path to scaling operations.

Comprehensive Support and Service

Rocket Machine Works provides full, ongoing support for its machinery, encompassing installation, operational training, and responsive field service . This commitment ensures maximum operational uptime and minimizes troubleshooting downtime for clients.

Summary of Value

The RM-18 is not characterized by complexity; it is a durable, practical solution engineered for producers focused on reducing labor expenditure, ensuring compliance, and executing intelligent scale-up strategies , all while preserving floor space and upholding long-term reliability.

For an accurate assessment of performance tailored to your specific product requirements, contact Rocket Machine Works at 559-834-5002 . Their team will assist in defining the optimal speed, configuration, and Return on Investment (ROI) for your enterprise.

Optimize labor. Scale strategically. Secure product integrity.

The RM-18: Elegant engineering driving production excellence.