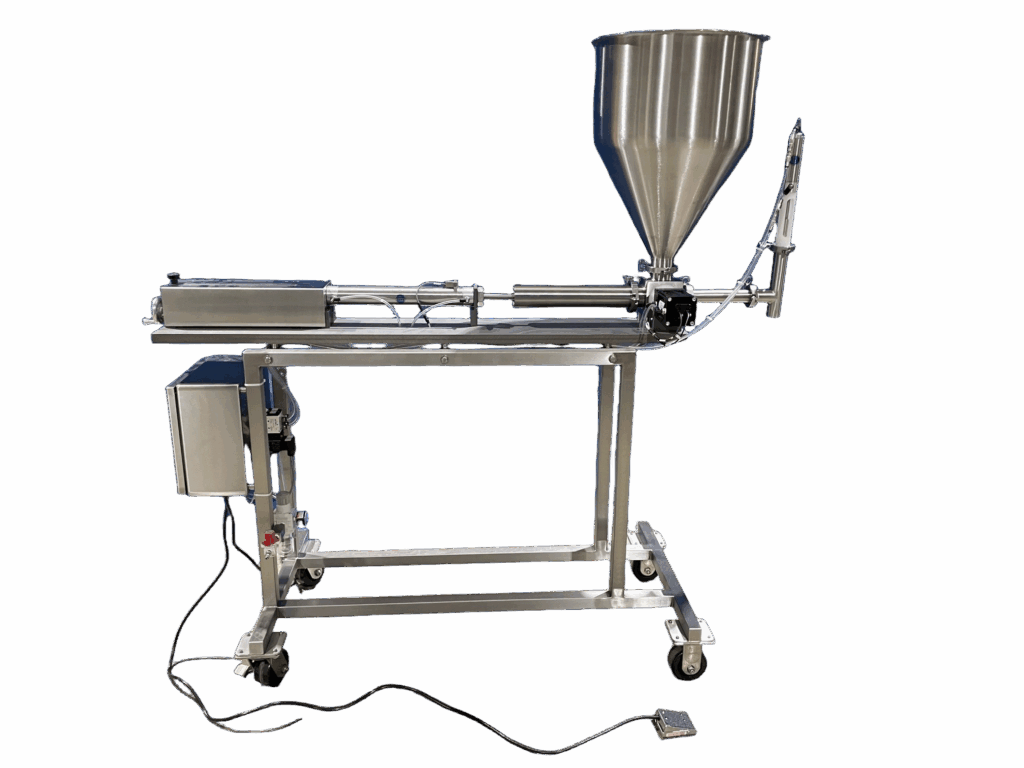

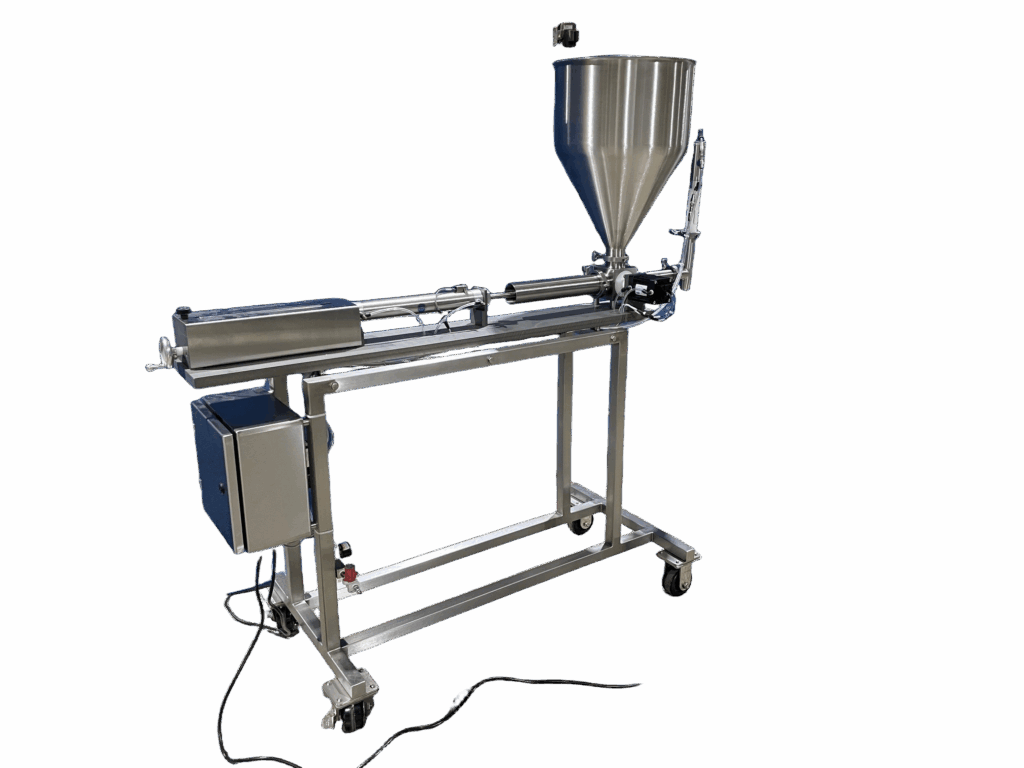

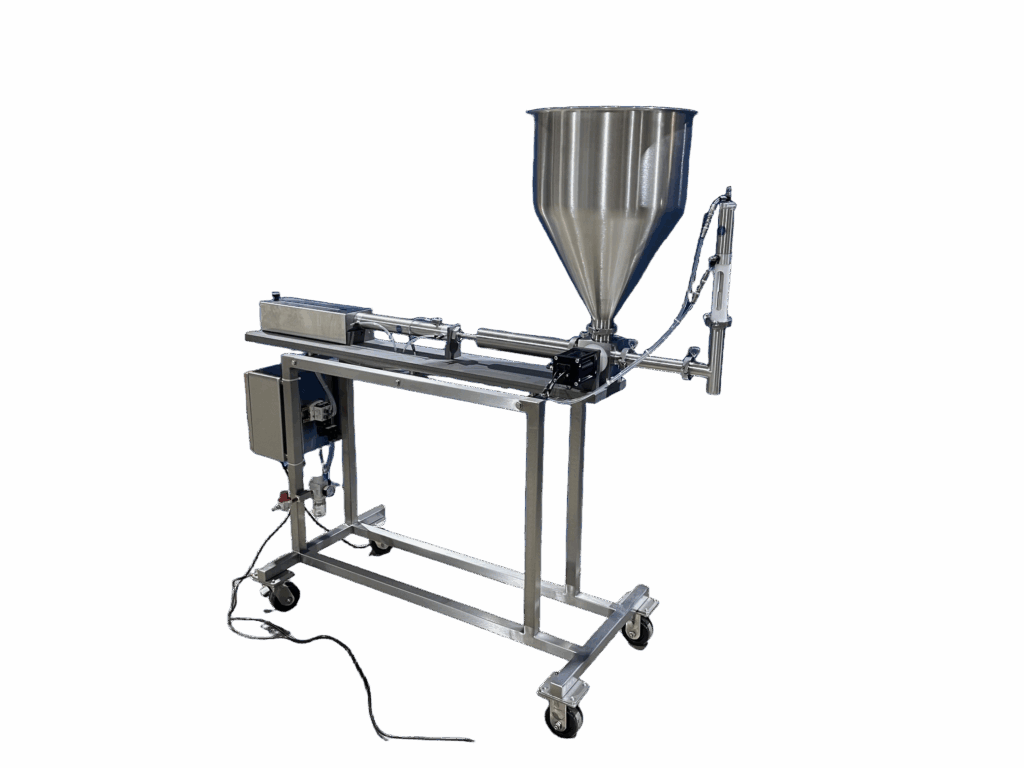

Piston Fillers for Food, Beverage, and More

Rocket piston fillers are built to deliver precise, repeatable fills from 1 to 128 ounces in a single shot, helping you maintain consistency across every container. All construction is built to high sanitary and durability standards, making these fillers ideal for demanding production environments.

Easy Operation and Fast Changeovers

Each piston filler includes a foot pedal for manual operation, giving operators simple, intuitive control during smaller runs or test fills. For automated production, the filler can be configured to mount on an existing line or machine, supporting seamless integration with your current Rocket equipment.

Hygienic, No-Tools Clean Up

The filler is designed for fast, no-tools disassembly so operators can clean product-contact parts quickly between shifts or product changeovers. Smooth, accessible surfaces and sanitary design help reduce downtime while supporting your food safety and quality protocols.

Flexible Container Sizes and Components

A variety of valves, nozzles, and supply reservoirs are available to match a wide range of products and container formats. This flexibility allows one piston filler to serve multiple lines, container sizes, or package styles with minimal adjustments.

Applications: From Thin Liquids to Chunky Products

Piston fillers handle an extensive viscosity range, from thin beverages to thick, chunky products. Typical liquid applications include sauces, chunky sauces, soups, beverages, dairy products, cosmetics, and personal care items, while dry applications include granular and other free-flowing products.

Contact us about your needs and we will line you up with the best machine for your production.