Meet the RM-36: High-Volume Precision in Rotary Filling and Sealing

In today’s competitive food and packaging landscape, operational efficiency is paramount. For producers dealing with mid-to-high volume throughput and larger container sizes, the equipment must deliver performance, durability, and compliance without compromise.

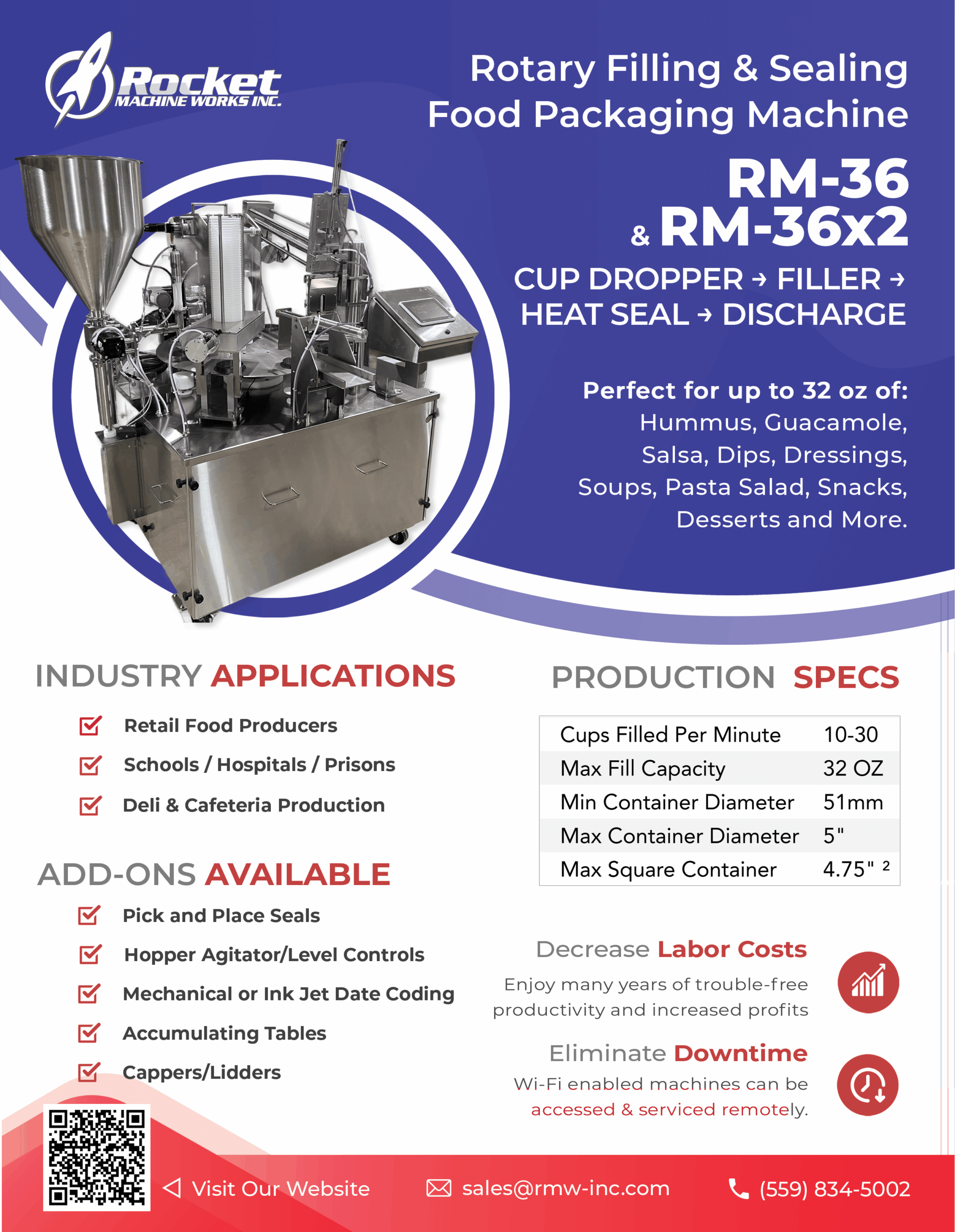

Introducing the RM-36 Rotary Filler and Sealer from Rocket Machine Works: a high-capacity system engineered to elevate your production while simultaneously reducing overhead. Designed specifically for larger cups and greater fill volumes, the RM-36 is the reliable workhorse you need to meet escalating demand.

Unmatched Speed and Precision for Higher Volumes

The RM-36 is an advanced eight-position rotary platform built for sustained output. This machine delivers superior production speeds, achieving an output of 10 to 30 cycles per minute , depending on the viscosity and volume of your product.

Crucially, the RM-36 accommodates a substantial range of containers, making it highly versatile:

- Container Dimensions: Handles cups from 51 mm up to 5″ in diameter and square containers up to 4.75″×4.75″.

- Fill Volume: Processes maximum fill volumes up to 32 oz , ideal for large deli salads, family-size dips, or prepared meal components.

Precision is guaranteed by a servo-driven fill system , ensuring consistent, accurate dosing for every container. This mechanism minimizes product give-away and maximizes batch uniformity.

Engineering Excellence and Regulatory Compliance

The RM-36 is built to perform under the toughest sanitary conditions. Its design prioritizes longevity and seamless integration into highly regulated environments:

- Robust Construction: The machine utilizes full stainless steel construction and is equipped with NEMA 4x, IP 67 rated wash-down components , facilitating rigorous cleaning and sanitization protocols required in food production.

- Integrated Quality Control: The mechanical motions are driven by a highly precise Cam Indexer & Camshaft Drive , ensuring every motion is reliable and trouble-free. Features like Container Denesting and the “no container, no fill; no container, no seal” logic eliminate material waste and safeguard product integrity.

- Compliance Guaranteed: The RM-36 is manufactured to meet or exceed USDA, FDA, and NSF standards , providing operators with total regulatory confidence.

The machine offers exceptional sealing capabilities, accommodating either roll stock film or pick-and-place seals for a 100% airtight closure on plastic or foil, protecting product freshness every time.

Scalability and Remote Service Capabilities

The RM-36 is designed not just for today’s needs, but for tomorrow’s growth. It offers immediate production scaling, processing up to three containers per cycle depending on the diameter. Optional add-ons include a second or third fill position for layered products, hopper agitator/level controls for challenging ingredients, and a Video Jet Date Coder for seamless batch and expiration coding.

Perhaps its most valuable modern feature is the Smart Panel Design . Each unit is equipped with a remote access module, enabling Rocket Machine Works to provide remote service and support. This capability allows technicians to diagnose and often resolve issues instantly, drastically reducing potential downtime and eliminating the wait for a service technician, a critical advantage in time-sensitive operations.

By integrating the RM-36, producers are not just buying a machine; they are securing a reliable, high-speed solution that is engineered to lower labor costs and provide a clear, scalable path for expansion.

To find the optimal configuration and determine the precise ROI for your high-volume packaging needs, we encourage you to contact Rocket Machine Works today.

Call Rocket Machine Works at 559-834-5002 to launch into new growth.