Die Cut Tray Sealer: Inline Precision for Film and Foil Applications

Available in the DTS-8 and th DTSx2

In high-volume food processing, efficiency and packaging integrity are paramount. While rotary systems excel for cups, inline operations requiring the meticulous sealing of trays, bowls, and uniquely shaped containers demand specialized technology.

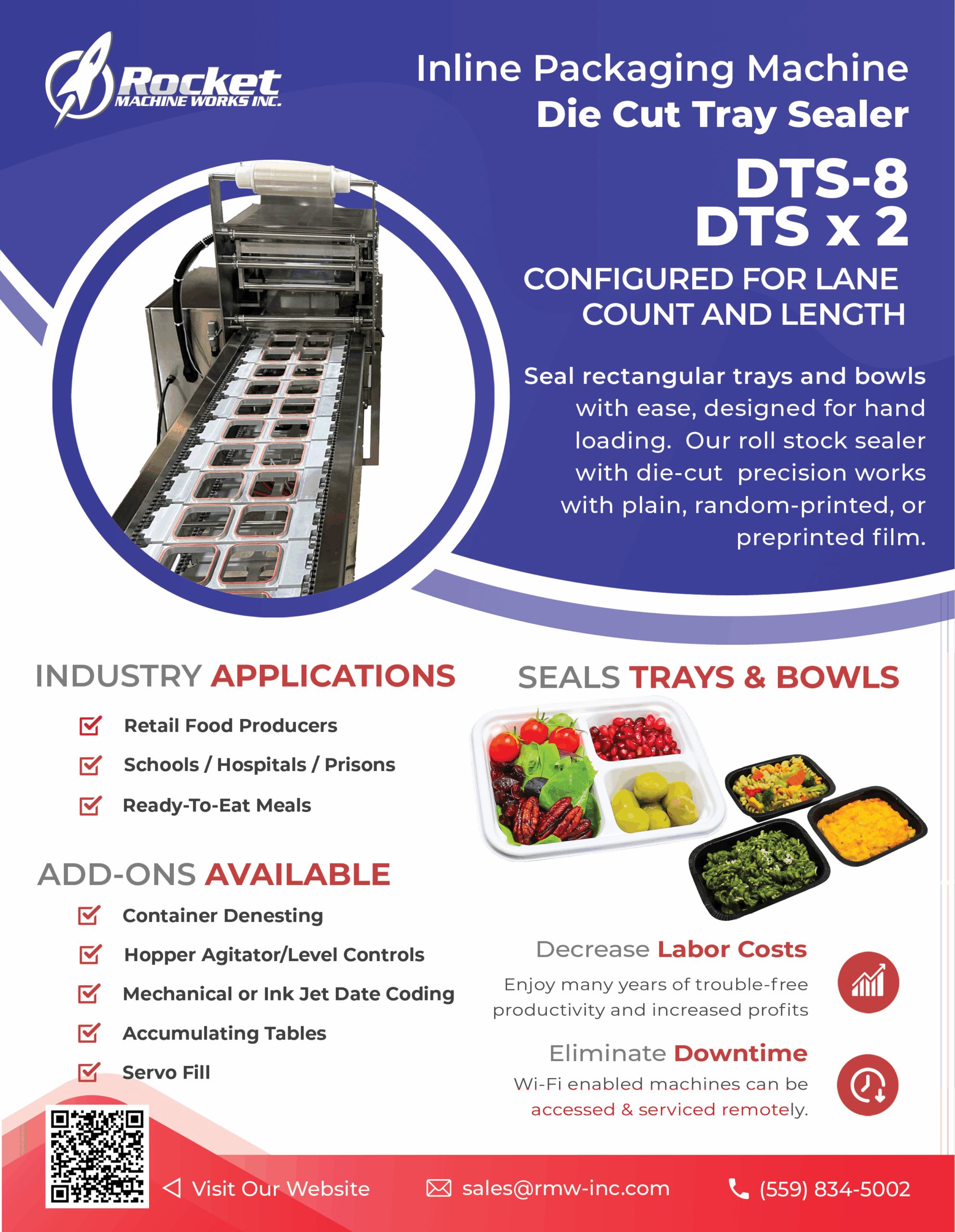

Rocket Machine Works introduces the Die Cut Tray Sealer , an advanced inline solution engineered to provide maximum precision, minimal waste, and superior aesthetic quality for pre-filled rigid packaging.

The Die Cut Difference: Superior Aesthetics and Efficiency

The Die Cut Tray Sealer is defined by its method: it uses a roll stock sealing film that is applied and then precisely trimmed to the exact contour of the tray. This “die cut” process delivers several critical advantages over simpler square-cut or top-seal applications:

- Precision Finish: It ensures a clean, contoured edge that perfectly matches the container, providing a highly professional and premium visual presentation for the consumer.

- Minimized Waste: The machine includes an efficient scrap take-up system that collects the excess film web, streamlining operations and reducing floor clutter and manual handling.

- Versatility: The system accommodates plain, random print, or accurately registered preprinted film , ensuring brand aesthetics are perfectly aligned every time.

High Performance in a Compact Inline Footprint

Engineered to integrate seamlessly into existing conveyor lines, the Die Cut Tray Sealer operates at superior production speeds, achieving 10 to 30 cycles per minute . Depending on the size of the packaging, it can be configured to seal up to six containers per cycle , offering a high-density solution for boosting throughput without sacrificing floor space.

The system is highly flexible, designed for a broad range of containers commonly used across various sectors:

- Container Compatibility: Perfect for rectangular trays, bowls, deli cups, and containers made from PET, Polyethylene, Polypropylene, and sustainable materials.

- Precision Control: Featuring Servo Index capabilities and a Variable Speed Drive, operators can precisely control film advancement and container movement through the HMI, maximizing speed for various products.

- Multi-Lane Filling: The system is capable of accommodating optional secondary and tertiary fill positions for products requiring multiple layers or components.

Built for Industrial Compliance

Reliability and regulatory adherence are non-negotiable foundations of the Die Cut Tray Sealer.

- Sanitary Design: The unit is constructed with full stainless steel and includes NEMA 4x, IP 67 rated wash-down components , ensuring it withstands rigorous cleaning protocols and maintains compliance within demanding food processing environments.

- Guaranteed Standards: The machine is manufactured to meet or exceed USDA, FDA, and NSF requirements .

- Operational Excellence: Features like the Cam Indexer & Camshaft Drive for mechanical motions ensure reliable, trouble-free operation cycle after cycle.

For manufacturers requiring a highly finished, airtight, and compliant seal on their rigid packaging, the Die Cut Tray Sealer provides an efficient, precise, and dependable inline solution that is proudly Made in USA .

To explore the precise throughput and configuration required for your specific packaging objectives, contact our engineering team.

Call Rocket Machine Works at 559-834-5002 to discuss integrating the Die Cut Tray Sealer into your production line.