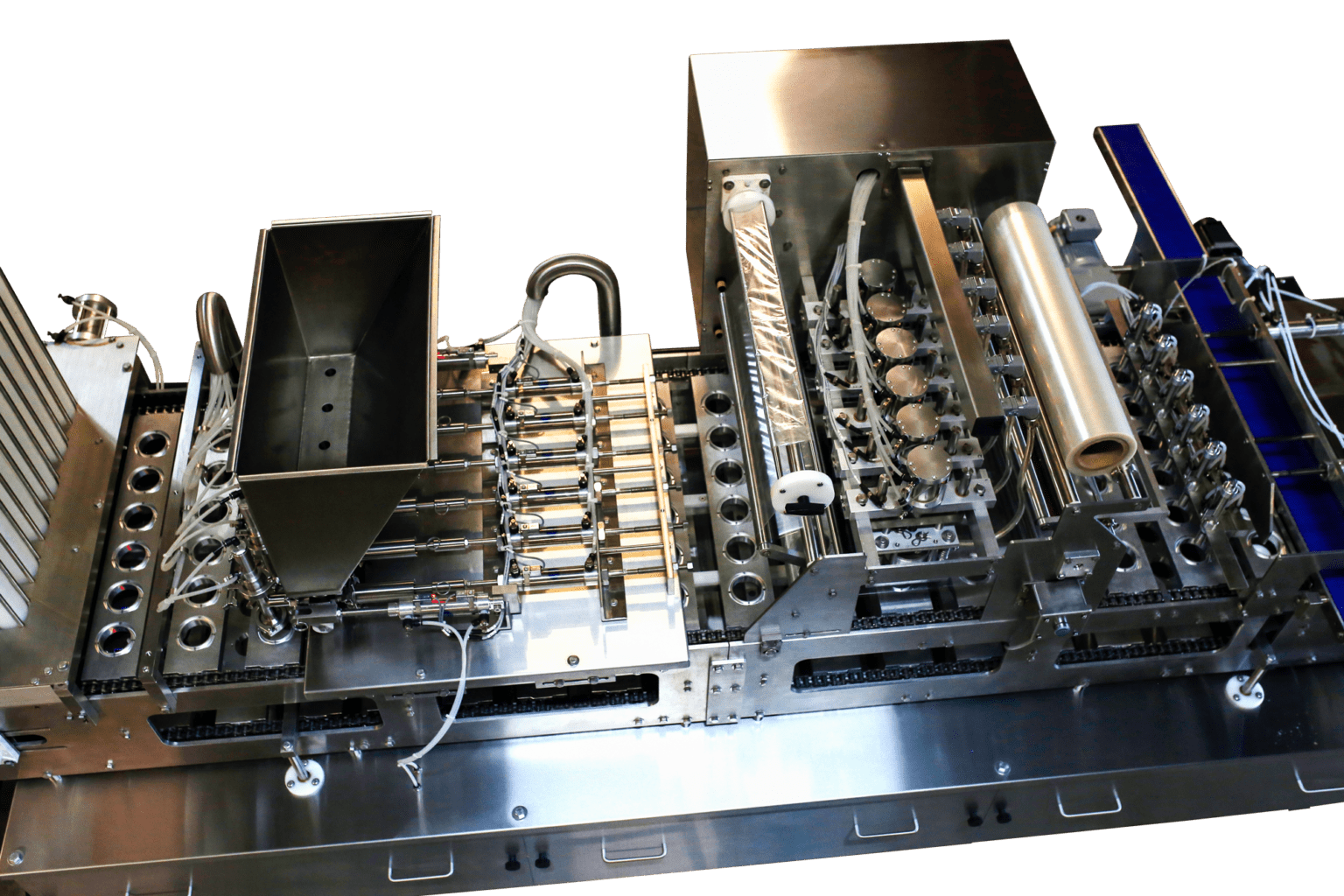

Elegant Engineering Meets Operational Efficiency

Heavy duty machines that can run 1-8 cups at a time. Speeds from 20 - 300 cups per minute.

Superior Production Speed

- Fits Containers from 1″ to 8″ Diameter and up to 6″ in height

Features include:

- Servo Index

- Variable Speed Drives

- Registered Print Sealing

- Over Capping

- Date Coding

Multiple Fills

- Mechanical

- Pneumatic

- Electro-Mechanical

Meets Or Exceeds Standards

- USDA

- FDA

- NSF

Service & Support

- Eliminate Downtime. Each machine has a machine a computer that allows us to fix and clear issues remotely. No need to wait for a service tech to come to your location.

Reduce Labor Costs. Scale Instantly With Additional Machines. Choose an Existing Design, or Custom Built For Your Exact Needs

The reason most companies buy our predictable, dependable machinery is to save hundreds of thousands of dollars per year on labor costs.

In-Line Filling and Sealing Packaging Machines offer you a durable, efficient solution when you need solid production without compromising floor space. Made to meet or exceed FDA, NSF and USDA standards, these machines have all stainless steel construction and direct wash down components.

We build several sizes depending on your production requirements, from only one container per cycle to as many as four containers per cycle. Features include cam index and lift motions, no container no fill, no container no seal, and other add-ons such as hopper agitator/level controls, mechanical or ink jet date coding, and accumulating tables.

In-Line Filling and Sealing Machines in Action

Custom Machines Built For Your Exact Needs

Perfect Seal Every Time

100% Air Tight. Plastic or Foil.

Optional: Roll Stock Film “Clear or Random Printed”

Expandable Production

As many as 6 containers per cycle depending on their diameter. Optional 2nd & 3rd Fill Positions.

Installation and Training

Our high quality manufacturing standards are only outmatched by our support and service excellence.

1. What products and containers are best suited for your In-Line Filling and Sealing Machines?

Our In-Line Filling and Sealing Machines are ideal for rigid packaging equipment—specifically for filling and sealing containers with a film seal on top, such as cups, tubs, and clamshells. They’re commonly used by food manufacturers and processors for products like salsa, hummus, ready-made meals, deli salads, fresh fruit, and snack foods.

2. What production speed can I expect from an In-Line machine?

In-Line filling/sealing machines can handle up to 10 lanes and are designed to increase productivity. They are built to help ensure you deliver your product on time, which is critical when working with perishables.

3. Are your machines easy to clean and compliant with food safety standards?

Yes. Our machines are designed with sanitation and cleanliness in mind. We highlight design features that make them easy to clean (stainless steel construction), and they are built to Meet or Exceed USDA, NSF, and FDA Standards.

4. How does Rocket Machine Works help minimize expensive downtime?

We minimize downtime through reliable, durable construction and superior support. Unlike some competitors, our machines use non-proprietary components that can be sourced from standard suppliers like McMaster-Carr. This means less downtime when maintenance is inevitably needed. Issues can also be fixed remotely via a computer installed in each machine, meaning no need to wait for a service technician to come to your site.

5. Can your In-Line machines accommodate my specific container size and material?

Yes, our machines are built with customization in mind. We can accommodate a wide range of cup and tray sizes and work with various materials (foil, plastic, paper films). We encourage you to ask: “Can I run this container on this machine?”, and we can address compatibility with standard container sizes (e.g., 50mm, 60mm, 75mm cups).

6. Where are Rocket Machine Works machines designed and built?

Our machines are proudly Made in the USA. They are designed, engineered, machined, fabricated, and assembled in California. We emphasize that we are a local, “family” business.

7. What is the value proposition of choosing a Rocket Machine Works machine over a competitor?

Our machines are the “Honda Accord of the industry”—they are dependable, very reliable and last a very long time. We position ourselves as offering good value with quality. Our primary value proposition is increasing productivity and minimizing labor costs, giving you the confidence that you will deliver your product on time.

8. Do you offer equipment for the rest of my packaging line?

Yes, we provide a variety of ancillary or “downstream equipment”. This includes packaging conveyors, accumulation tables, piston fillers, denesters, date coders (VideoJet partnership), and case packing.

9. What services do you provide after the purchase?

We stand by our equipment and offer ongoing support. We will build your machine from scratch, deliver it, install it, and train your employees on how to use it. Our remote service capabilities also ensure we can address issues quickly, reducing your potential downtime.

10. Does a new machine have to be custom-built, or are there standard models?

We offer base models with a solid product line that can be customized to your specific needs. While you can choose an existing design, every machine we produce is customized to your product and operational needs.