Elegant Engineering Meets Operational Efficiency

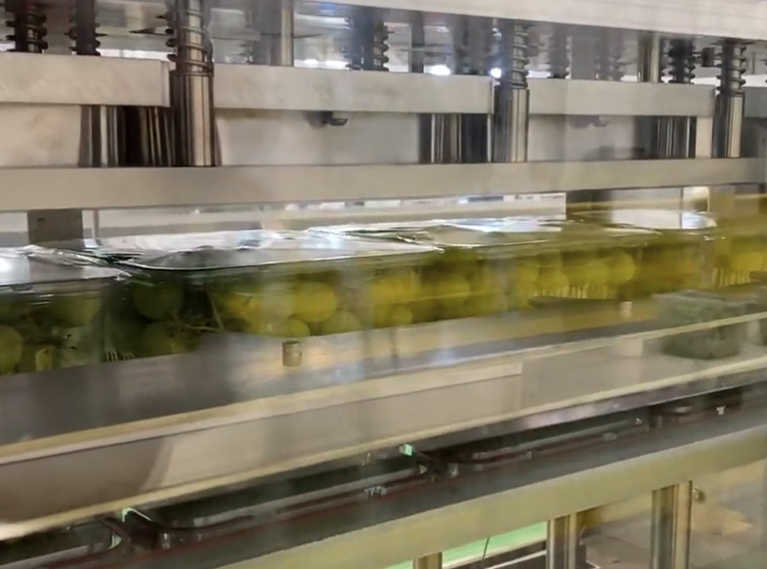

An inline high volume sealer for die-cut foils or roll stock film with die cut.

Superior Production Speed

An inline sealer that will accept trays or bowls from a conveyor and feed them to an exit conveyor when finished. No added curves, keeps your line linear. One machine can be configured to seal from 3 – 8 containers at a time with rates up to 120 per minute.

*Depending on product and volume. For precise speed of operations:

Call To Ask

559-834-5002

Features include:

- Full Servo Control

- Die Cut Roll Stock Seal

- Pre-Printed Film

Add-Ons Available:

- Gas Flushing

- Thermal Transfer Printer

Meets Or Exceeds Standards

- USDA

- FDA

- NSF

Container Types (Cups & Trays)

- Deli Cups

- Trays

- Sustainable Packaging

- PET Series

- Polyethylene /Polypropylene

Service & Support

- Eliminate Downtime. Each machine has a remote access module that allows us to fix and clear issues remotely. No need to wait for a service tech to come to your location.

Reduce Labor Costs. Scale Instantly With Additional Machines. Choose an Existing Design, or Custom Built For Your Exact Needs

The reason most companies buy our predictable, dependable machinery is to save hundreds of thousands of dollars per year on labor costs.

The Continuous Motion Tray Sealer Line of In-Line Filler and Sealer packaging Machines offers you a durable, efficient solution when you need solid production without compromising floor space. Made to meet or exceed FDA, NSF and USDA standards, these machines have all stainless steel construction and direct wash down components. Part of our commitment to service excellence is by providing content on our website that is helpful for you. The Continuous Motion Tray Sealer for food processing by Rocket Machine Works is made in USA, and designed and manufactured in California.

Perfect Seal Every Time

100% Air Tight. Plastic or Foil.

Optional: Roll Stock Film “Clear or Random Printed”

Expandable Production

As many as 6 containers per cycle depending on their diameter. Optional 2nd & 3rd Fill Positions.

Installation and Training

Our high quality manufacturing standards are only outmatched by our support and service excellence.