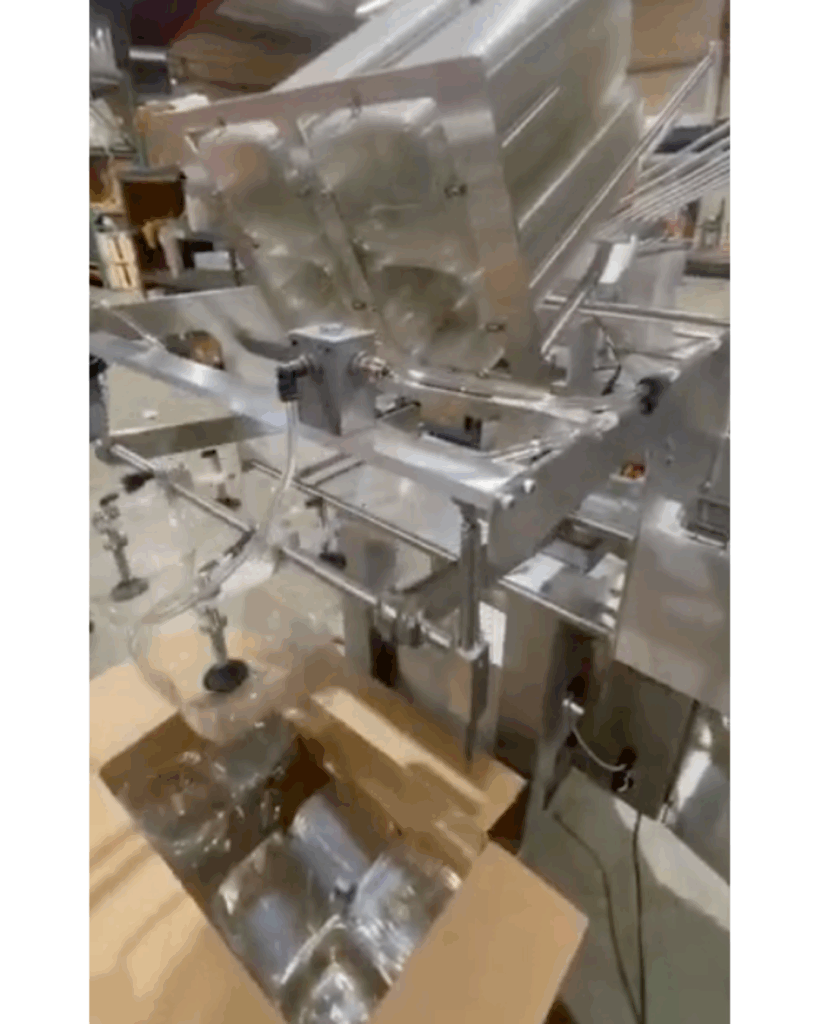

Denesters for Food and Dairy Packaging

Rocket denesters automatically separate and place cups, trays, and lids into your production line, removing repetitive manual tasks that slow operators down. They are designed to start your containers in the correct position and orientation so they feed cleanly into Rocket filling and sealing equipment.

Gentle, Reliable Container Handling

Each denester pulls a single cup or tray from a vertical magazine and places it onto the conveyor or into machine carriers with precise, repeatable motion. This controlled handling helps prevent jams, misfeeds, and container damage, supporting continuous operation on high-output lines.

Built for Washdown and Sanitary Environments

Rocket denesters feature robust stainless steel construction and washdown-ready designs suited for food, beverage, and dairy plants. Smooth, accessible surfaces and hygienic assemblies support fast cleaning and help you maintain your food safety and quality protocols.

Flexible Formats and Line Integration

Denesters can be configured to handle a wide range of container types, including plastic, paper, foil, and board-based cups and trays in multiple shapes and sizes. They integrate with new or existing Rocket rotary and inline lines so you can add automated denesting without major changes to your current equipment layout.

Boost Throughput and Reduce Labor

By automating tray and cup placement, Rocket denesters help reduce manual labor at the front of the line and improve overall line speed. Consistent, accurate denesting keeps product moving toward filling, sealing, and lidding, supporting higher productivity and less unplanned downtime.

Contact us about your needs and we will line you up with the best machine for your production.