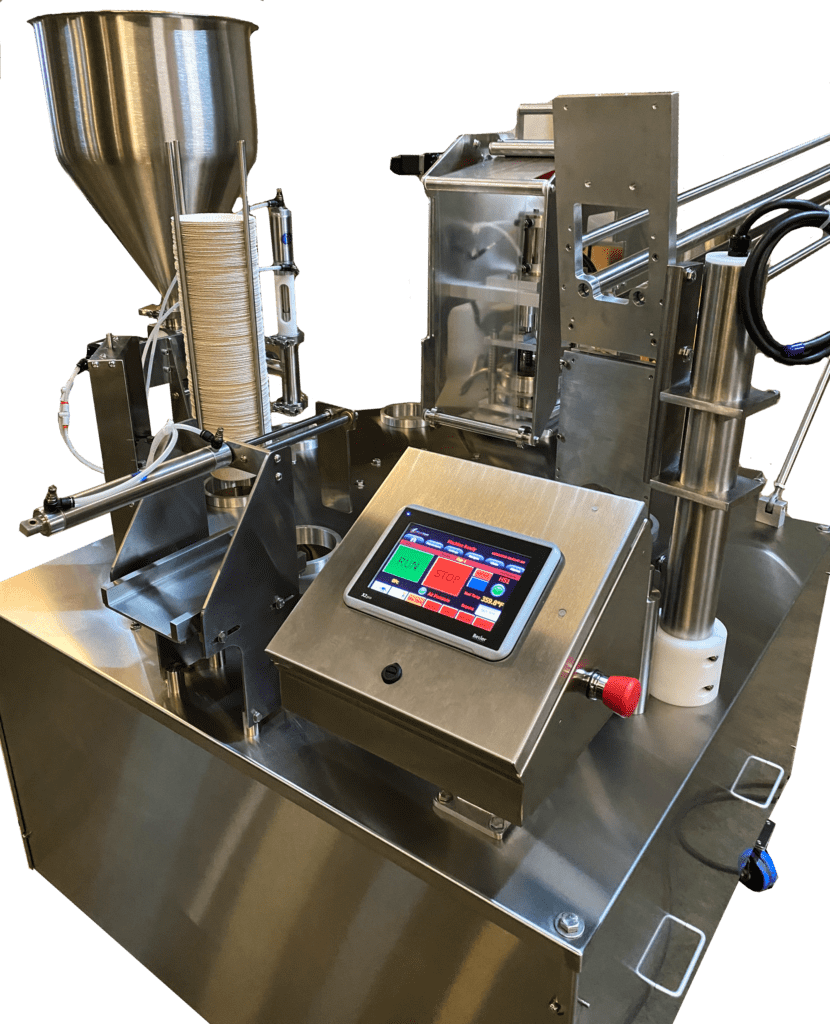

Efficient, sanitary, and tailored solutions to meet the growing demands of hummus producers. Hummus producers trust our high quality filling & sealing food packaging machines.

As the popularity of hummus continues to grow, so does the need for reliable, hygienic production processes. Contamination risks, inefficiencies, and scaling issues can halt production and impact product quality. That’s where Rocket Machine Works comes in.

Our filling and sealing machines are designed to uphold the highest standards of cleanliness while reducing downtime and ensuring your operation stays efficient and compliant with food safety regulations.